Innovation through ultra-modern manufacturing technology

Sparkasse Duisburg donates 5-axis milling machine to Rhine-Waal University of Applied Sciences

Computer-controlled milling machines are highly innovative tools used in many industry and trade applications. Thanks to a generous donation of 8,000 euros from the Sparkasse Duisburg, which was officially presented to the University today, this advanced technology will soon appear in the FabLab of Rhine-Waal University of Applied Sciences, our highly modern manufacturing facility on the Kamp-Lintfort Campus, in the form of an ultra-modern 5-axis milling machine.

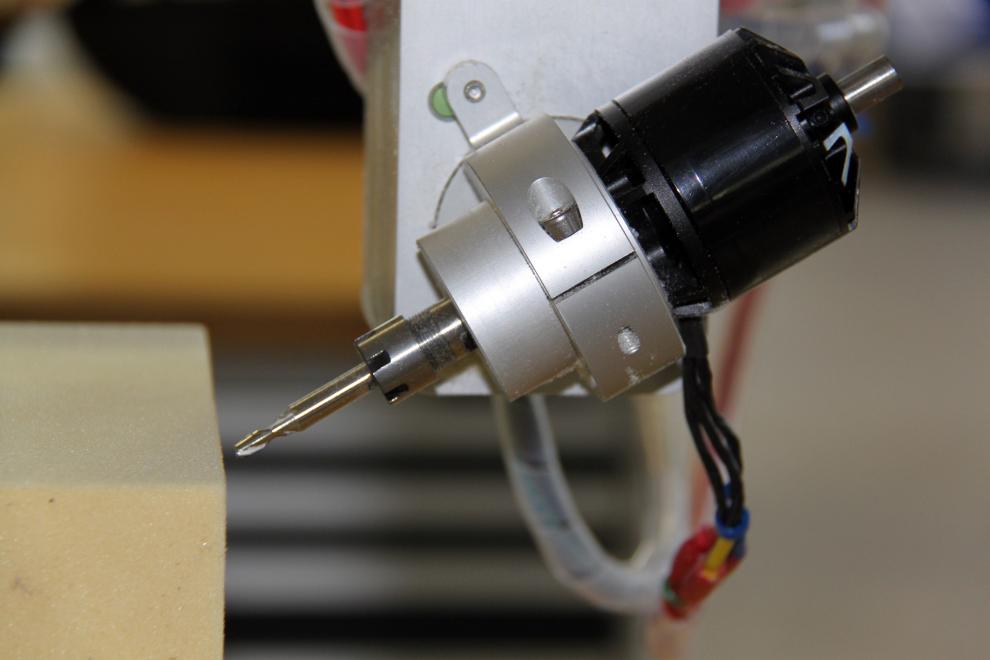

Computer numerical control (CNC) milling machines are used shape blocks of materials – whether wood, plastic, ceramics or metal – into predefined parts by ‘milling away’ excess materials. Before the milling process begins, a three-dimensional blueprint of the part is created using computer design software. This blueprint is fed to the milling machine, which then automatically shapes the part according to specification. This process allows users to carve reliefs into blocks of wood or other flat surfaces. These relatively ‘simple’ processes can be carried out by any 3-axis milling machine. More complicated forms, for example with corners and edges, require machines with additional axes such as the new 5-axis milling machine at Rhine-Waal University of Applied Sciences. This machine allows the milling tool to approach the material from all sides and angles, which makes it ideal for manufacturing complex machine components, for example.

“We see the connection between research, studies and teaching as an important building block for the meaningful comparison, renewal and transfer of knowledge. This requires excellent facilities with ultra-modern tools, however. Our newly acquired 5-axis milling machine signifies an important addition to the technical infrastructure of our University and creates new opportunities for applied, hands-on training for our students,” said Dr Heide Naderer, President of Rhine-Waal University of Applied Sciences.

The 5-axis milling machine will be used primarily for teaching purposes. The FabLab in Kamp-Lintfort is an important facility that allows students to gather experience in the use of many modern manufacturing technologies. “We decided on this machine in particular because it’s very user friendly and is known for its reliability, which is particularly important when it’s planned for use by many students. The practical experience students will acquire through the use of this machine is applicable to similar or even larger machinery,” said Professor Dr Karsten Nebe, FabLab Director.

The acquisition of the new 5-axis milling machine was made possible by a generous donation of the Sparkasse Duisburg bank. “Our donation is a long-term investment in education and the continued structural transformation of Kamp-Lintfort. We are very pleased to support the FabLab in particular, as both students and non-students can profit from the combined use of the facility,” said Ulrich Schneidewind, deputy chair of the Sparkasse Duisburg.